Archives- Projects from my younger years.

Here are a selection of projects from my younger years. I never really bothered to document these projects or ideas, as I had no interest in sharing them at the time. I was purely doing this for myself and my own enjoyment.

Table I built cira 2009

Mountain Board Ramps

Before I got into mountain biking I was an incredibly keen mountain boarder. I was keen on skateboarding at a young age, but living in a rural setting we there was no local skatepark for me to walk to, and our road was covered in horse manure. I took up mountain boarding as it was more accessible living in the countryside, and built these ramps.

Dodgy joinery with nails poking out and split wood, I built these two ramps and set them up in the wood behind our house.

I think this was the third or fourth ramp I had built. As you can see the carpentry was a lot better at this point and the ramp was a lot less sketchy.

Oscillating Compressed Air Engine

At this point of my making career I was fascinated with people building oscillating steam and compressed air engines on youtube. I really wanted to buy a lathe and a mill, but at my young age this wasn’t really suitable. I built a oscillating engine out of old bits of plywood, a lolly pop stick and skateboard hardware. The rubber tube to blow the air into was from a catapult, and the aluminium backing plate was cut out of an old aluminium quality street biscuit tin. I cast the piston using JB weld. I discovered that if you thinly cover the internal surface of the copper tube with JB weld, you can cast an accurate piston.

All the parts separated.

Homemade Mini Bike - 2012

In my early teenage years, I was inspired to build this bike after finding the plans for the Tom Thumb Minibike online. I didn’t have access to a tube bender and I wasn’t very good at fabricating, so I built it out of box section. I think I only rode it a handful of times before I mixed the two stroke fuel incorrectly and the engine blew up. The material for the galvanised handlebars was a plant support found in the garden. At the time I thought mig welding galvanised material was fine.

The front forks tacked together. There was no bearings in the headtube, so the steering was very stiff as the bottom of the headtube rested on the bottom fork yoke. I remember the tubes from this fork coming from a school chair, hence why they’re still slightly powdercoated black on the left side.

The welding was very ropey, and the wheels were £2 from a carboot hence why the tires didn’t match.

The 50cc engine was from a chinese pitbike. It had a 1:30 fuel mix, but I didn’t really understand the concept of mixing fuel so it smoked lots and blew up quite quickly.

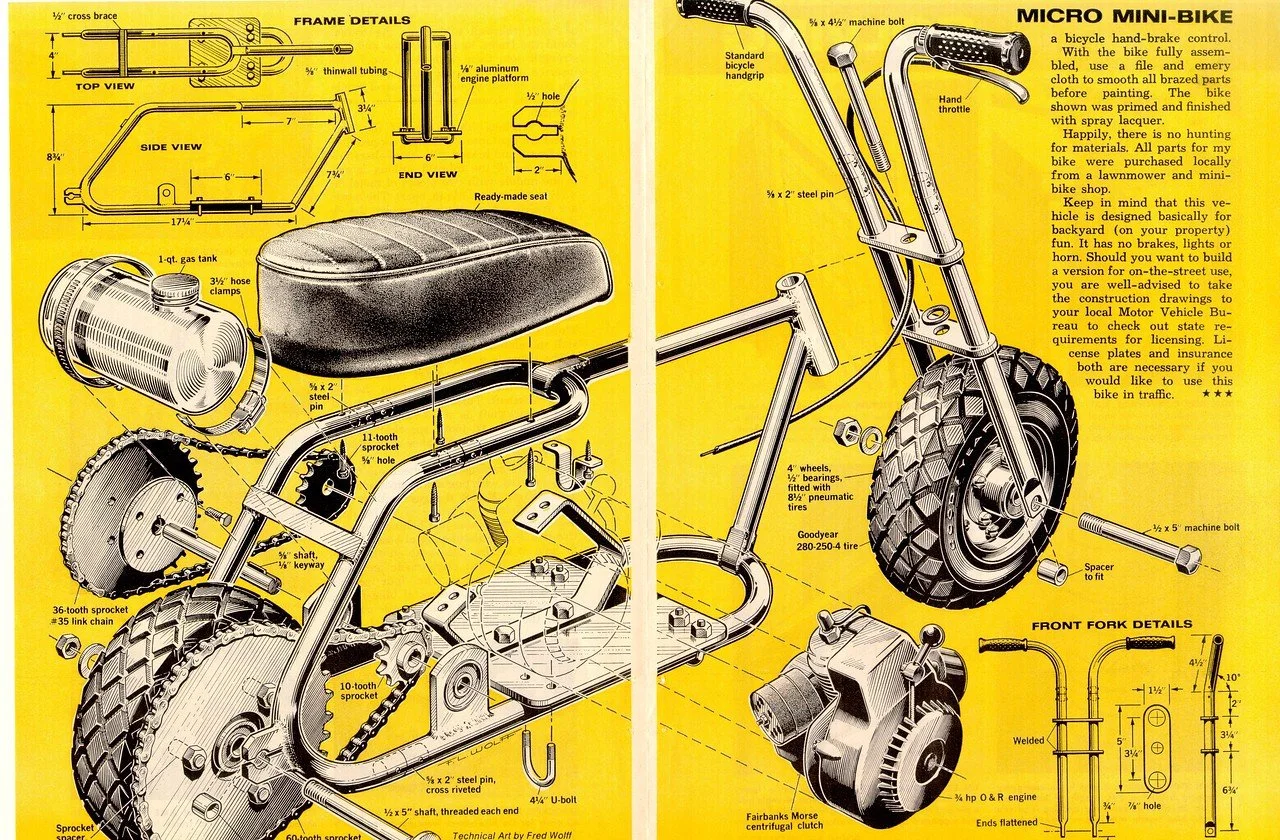

These are the plans I was inspired by:

Homemade Chain Guide - 2013

Back when I first started mountain biking, on my first bike (Kona Stinky- what else?!) I decided to build a homemade chain guide. I found this on my pinkbike account from back in 2012. Using jockey wheels from a broken Sora derailleur, the metal plates cut out of a 90 degree wall bracket and skateboard hardware for the bolts, a chain guide was born. It didn’t last long, and the sharp corners did a good job of cutting my calves.

Mountain Bike Bottle Cage/ Toolkit 2016

This was my A2 final project for A-Level Design and Technology. Whilst I enjoyed DT at school, and scored an A* at A-Level I also found it frustrating. As I had been designing and making things from such a young age, I was brought back to basics with a class of other students who hadn’t had the same making and creating journey as myself.

The idea of this came about as I wanted to be able to carry a water bottle, a pump and a multi tool on the bike, and not have to carry it in a rucksack. The water bottle was attached using a stretchy elastane band, and this was connected to the bike using neodymium magnets.

The multitool was cut using a 2 axis CNC mill. This meant the part required a lot of further finishing with files and emery paper. The hex keys were cut from a set. In the final design the hex keys should have been retractable, so only one key would be pushing through at any one time. The curved plastic part was vacuum formed acrylic, which was formed over a plywood mould.

I machined the pump on the lathe, and took the non return valve out of a budget rolson hand pump. I had never done any metalwork machining before, so this was quite an enjoyable challenge. I anodised these parts to make them tolerant to scratching and damage, whilst improving the look of the model.

The assembled unit out on a test ride for some light XC riding.